Furnace Improvements

Furnace Improvements

Click on any image to see a full size picture.

The next thing to do was make a proper lid. I have raised the level

of the wall of the rim in order that the refractory will sit proud & fit into the rebate in the furnace refractory.

Here the wet refractory is in the lid & I have made a vent hole

in it with a thin glass jar (not shown).

Any cylindrical object of the right diameter would work.

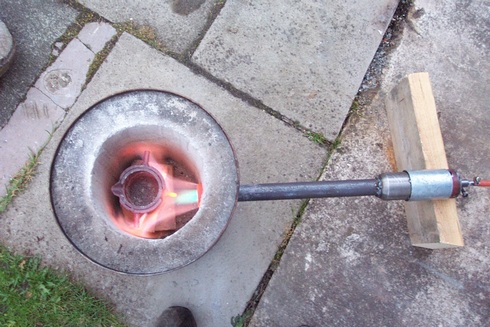

I have made a Bunsen type burner from plans on

Cameron McKeowns page

The main jet is a Tweco mig wire tip of 0.8mm diameter.

The flow rate is badly insufficient as you can see that the movable choke on the burner is almost fully closed.

Opening it causes the burner to go lean & flame out.

I have bored one of the tips (I bought several) to 2mm.

Why 2mm?

Because my 1.5mm drill snapped off in the previous tip I tried to drill.

I will try to make a 1.5mm jet soon though, as even with the choke fully open

I still cannot get complete combustion with the gas full on.

Putting the lid on doesn't help either!

This is it running at about 15psi.

Zero to zorch in under a second.

Patently major overkill for this furnace.